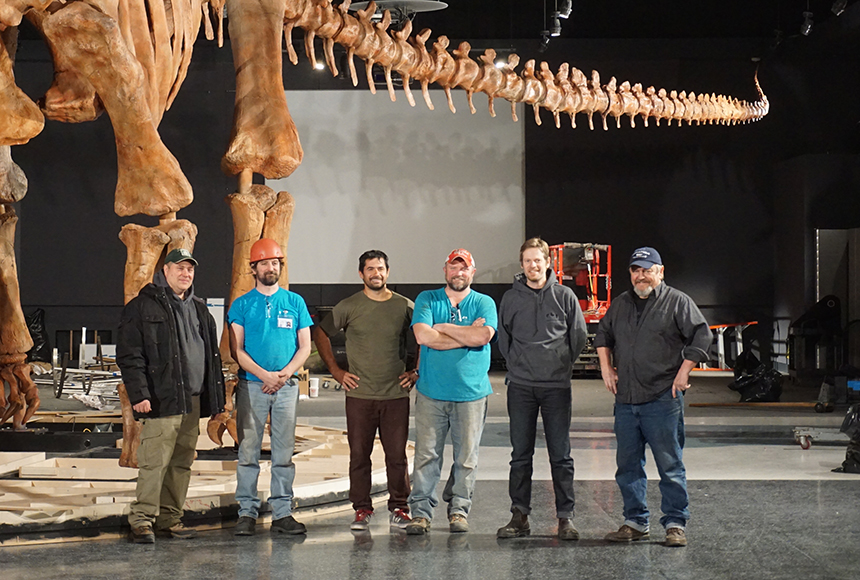

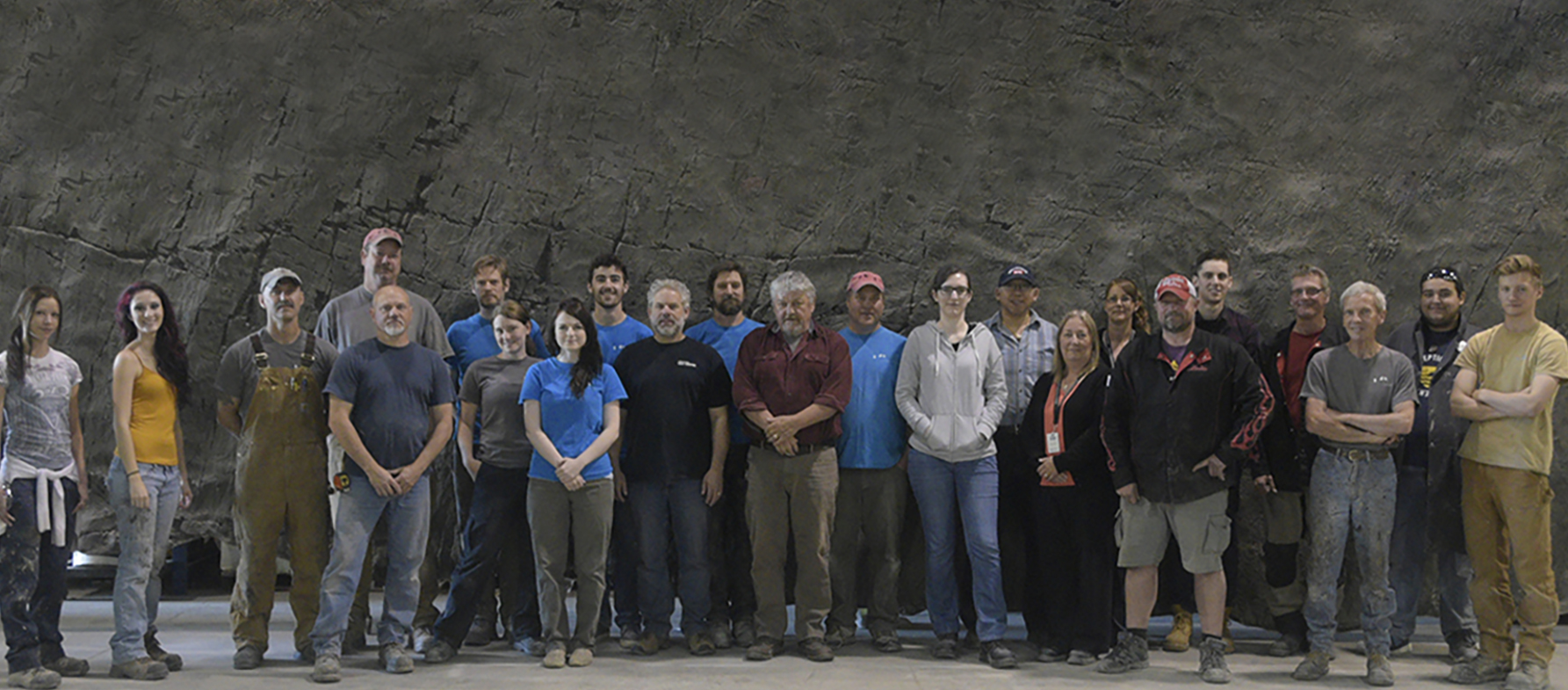

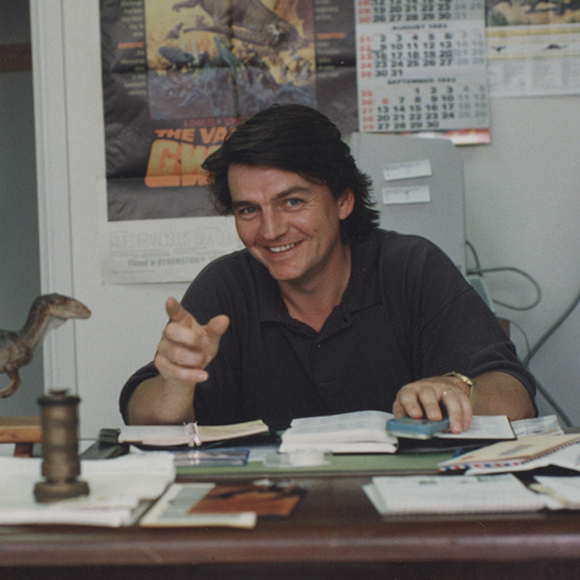

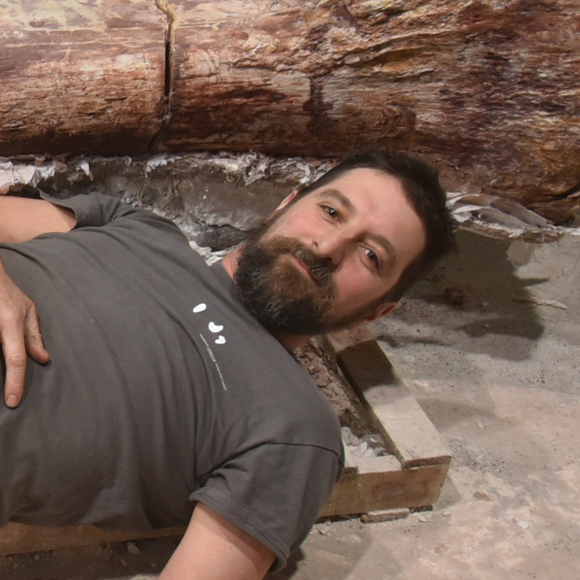

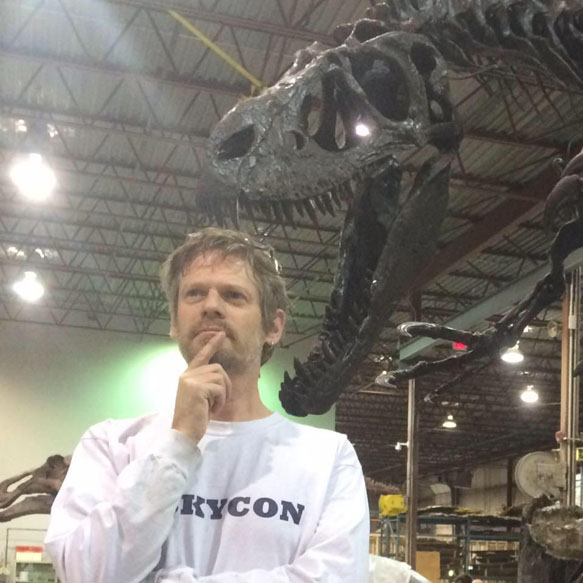

When RCI founder and president Peter May was interviewing at the Royal Ontario Museum for his first position working with dinosaur fossils back in 1977 he ended up rolling up his sleeves and getting his hands dirty checking out their tech. He wanted to know how they did their casts and molds. Ten years later, as Peter started staffing up for his new venture, Research Casting International, the same sort of people were drawn to join the team. The kind of people who are interested in rolling up their sleeves and getting their hands dirty. People who are interested in creating and preserving. The same thing drives the culture at RCI today. Like to Camp? Drive a 4X4? Get your hands dirty? Work with the latest tech and classic artisanal tools? You’ve come to the right place.

We are always interested in receiving resumes that we can keep on file. We would be looking for people who have skills in molding and casting, painting and sculpting, blacksmithing and metal fabrication, and fossil preparation.

Current Employment Opportunities:

Sales and Production Supervisor

Reports to: General Manager

Summary

Research Casting International is looking for a highly organized, self-motivated individual with excellent interpersonal and communications skills to work with clients and production staff for our aluminum/bronze foundry and concrete playground fabrication divisions. Competency with machinery and hand tools are an asset.

Duties and responsible for this position include but not limited to:

Sales and estimating for Foundry products

- Estimating for Casting and finishing of parts

- Estimating Mold making

- Estimating for Prototypes

- Maintaining and generating price lists

- Generation of marketing materials in conjunction with Marketing Manager

- Development of new products

Customer service

- Handling of new enquiries and clients

- Order confirmation and request for quotation processing

- Inventory management

- Tracking of all production orders and shipping

- Dispute resolution

Production Management

- Create schedules for production

- Coordinate with supervisor of the foundry and finishing area to meet order schedule

- Quality control and inspection

- Packing and shipping

- Pack lists and invoicing

- Ordering materials and supplies for foundry and shipping area.

Production

- Assist where and when needed with production: Polishing and finishing, MFI machine, Vibratory area, Stone fabrication

Cast Mounting Technician

Reports To: Cast Mounting Supervisor

Summary

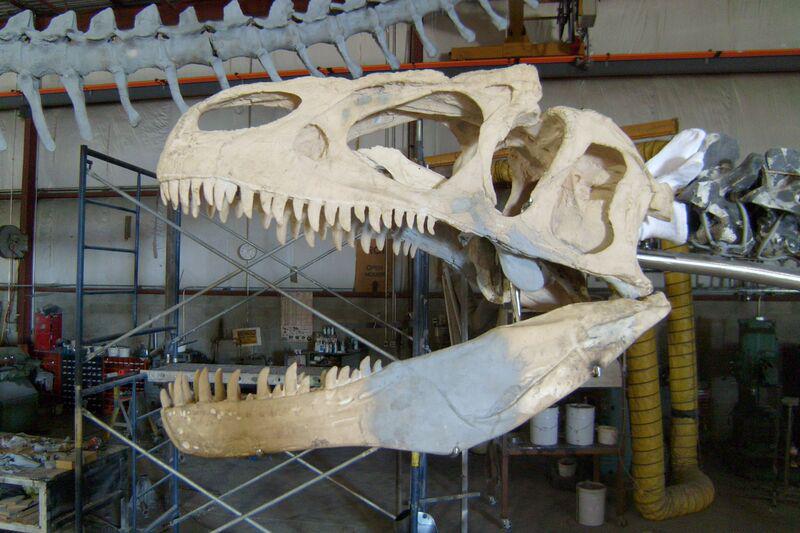

The position of cast mounting technician includes, but is not limited to assembly, metal fabrication, MIG welding, sculpting, installation, packing and crating. Responsibilities will be to complete assigned work in a timely fashion, work as a part of a team of like-minded individuals, potential to travel to job sites around the world installing museum exhibits fabricated at Research Casting International.

Core Competencies

- Quality Assurance

- Time Management

- Creative and Innovative Thinking

- Development and Continual Learning

- Problem Solving

- Accountability and Dependability

- Decision Making and Judgement

- Operating Equipment

- Ethics and Integrity

- Planning and Organizing

- Enforcing Laws, Rules and Regulations

- Communication

- Teamwork

Job Duties

- Read and interpret blueprints.

- Operate GMAW welding Machine

- Operate plasma or flame-cutting equipment.

- Operate metal shaping machines such as plate rolls, lathe, milling machine, drill press and Iron Worker

- Maintain safe work practices.

- Prepare input for various management and log reports.

- Provide data to assist in monitoring and tracking project budgets and project status.

- Review blueprints and specifications; ensure drawings and specifications will function as designed in environment intended for use.

- Schedule critical and non-critical activities effectively for project success.

- Develop goals and priorities; assign tasks and projects.

- Other assigned work as required.

Requirements

- High School Diploma, GED or equivalent.

- Possess a valid driver's license.

- Ability to work independently in a busy environment.

- Highly flexible, with solid interpersonal skills that allow one to work effectively in a diverse working environment.

- Able to effectively communicate both verbally and in writing.

- Able to work well under pressure.

- Strong attention to detail.

- Able to deal with people sensitively, tactfully, diplomatically, and professionally at all times.

- Computer literate an asset.

Work Conditions

- Hours 7AM to 3 PM 5 days a week.

- Physical ability to lift up to 50lbs.

- Travel to off-site locations may be required.

- Safety equipment will be required, e.g., steel-toed safety boots, safety glasses/goggles, etc.

- Overtime as required.

- Hazards associated with the trade.

- Work both indoors and outdoors.

- May be exposed to construction sites.

- Dental and Drug Plan

- Group RRSP

Welder Component

This job also requires experience and expertise for production welding, service & repair welding, prototype building, and fitter welding. Responsibilities will include the fuel-tank and card-lock repairs, fabrication of custom prototypes from supplied drawings, fabrication of custom jigs and fixtures to produce production parts that meet customer specifications, as well as the fabrication of metal structures using jigs and fixtures in a high paced production environment.

The use of various hand tools, machinery and equipment will be required to manufacture metal products. This position will work with Supervisors and Lead Hands to ensure continuous improvements in work cells, hitting quotas, welding according to pre-set parameters using MIG, ARC and TIG welding processes. The ability to scan in and out of work orders is a must. The Journeyman Welder will be required to assist the Design Department with insight and knowledge of superior manufacturing methods, perform random maintenance on returned products to be refurbished or re-worked to customer specifications, and have strong knowledge and skill in operating all metalworking machinery. Additionally, the Journeyman Welder will be required to read and understand production drawings, blueprints, work orders and other written instructions.